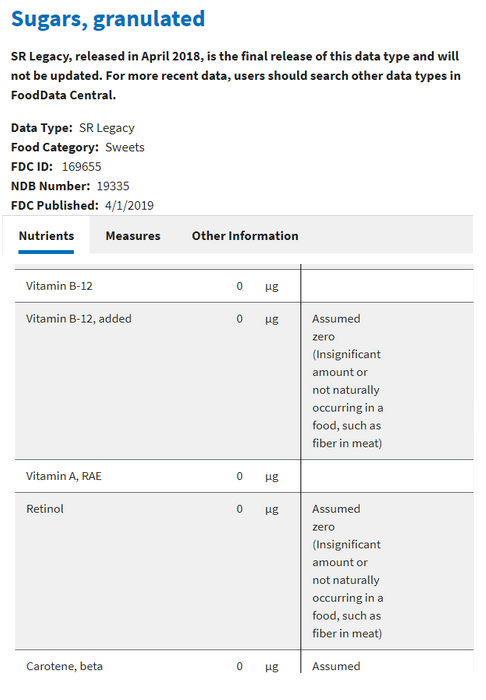

The process of making cane sugar generally includes seven stages, namely the preparation stage, the milling stage, the refining stage, the evaporation stage, the cooking stage, the turning stage and the completion stage. The rotating stage aims to separate the sugar crystals from the syrup or drops. Therefore, this stage is very important to control because at this stage trying to obtain sugar crystals in a pure form that is separated from the solution by means of centrifugation.

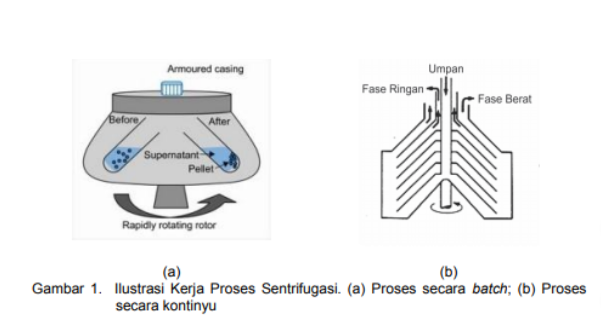

What is centrifugation? quoted from Chen and Chou (1993), centrifugation is a unit of operation that includes the separation of the material by the centrifugal force when the material is rotated (rotated). A good centrifugation system is needed to maintain sugar quality. The rotating process that is not good also results in the color of the sugar crystals not white but yellowish in color and the water content of the sugar crystals is still high because there are still drops or syrup that have not been separated from the sugar crystals.

There are two rotary tools, namely Low Grade Fugal and High Grade Fugal. Low Grade Fugal produces a rotation speed that is not too fast and is continuous which can be operated manually while the High Grade Fugal rotation produces a fast rotation speed, is discontinuous and operates automatically. This rotary tool is a rotating machine used to separate sugar crystals from the solution. In this rotary device there is a filter, the working system is by using centrifugal force so that the food is rotated and the strop or solution will be filtered and sugar crystals are left in the spin. In this process, crystal sugar and drops are produced. Crystal sugar is cooled and dried to reduce the water content.

The implementation of centrifugation is to separate the sugar crystals formed from the solution (syrup) which is centrifugally coated. In this separation can produce sugar, solution (klare or stroop) and drops. Sugar crystals are added with condensate water while in the rotary device. The function of adding condensate water is to wash the dirt and dissolve the remaining syrup. The working principle is that the centrifugal force will push the solution out through the holes in the filter in the form of a rotating drum while the sugar crystals are held. Sugar crystals will stick to the rotating wall while the solution will drop out as a result, the sugar crystals will separate from the solution.

Quoted from the Journal of Food Science and Agricultural Products, the centrifugation process can reduce the turbidity of sugar juice. Therefore, the spinning stage is very important, especially in maintaining the quality of processed sugar and the cleanliness of the sugar. It can be seen from the sugar crystals that are not white but yellowish in color and the water content of sugar crystals is still high because there are still drops or syrups that have not been separated from the sugar crystals.

De Vivace

De Vivace Back

Back